Powder coatings

The powder coatings market is constantly looking for new products that can improve productivity and to ensure adequate protection from corrosive degradation. In order to guarantee a good resistance against corrosion, in the field of powder coatings it is generally necessary to apply two layers of coatings on an appropriately pre-treated item. The first layer is denominated primer and it is usually based on an epoxy or epoxy-polyester chemistry. Instead, the second layer of coating is denominated top coat and it is generally based on a polyester chemistry.

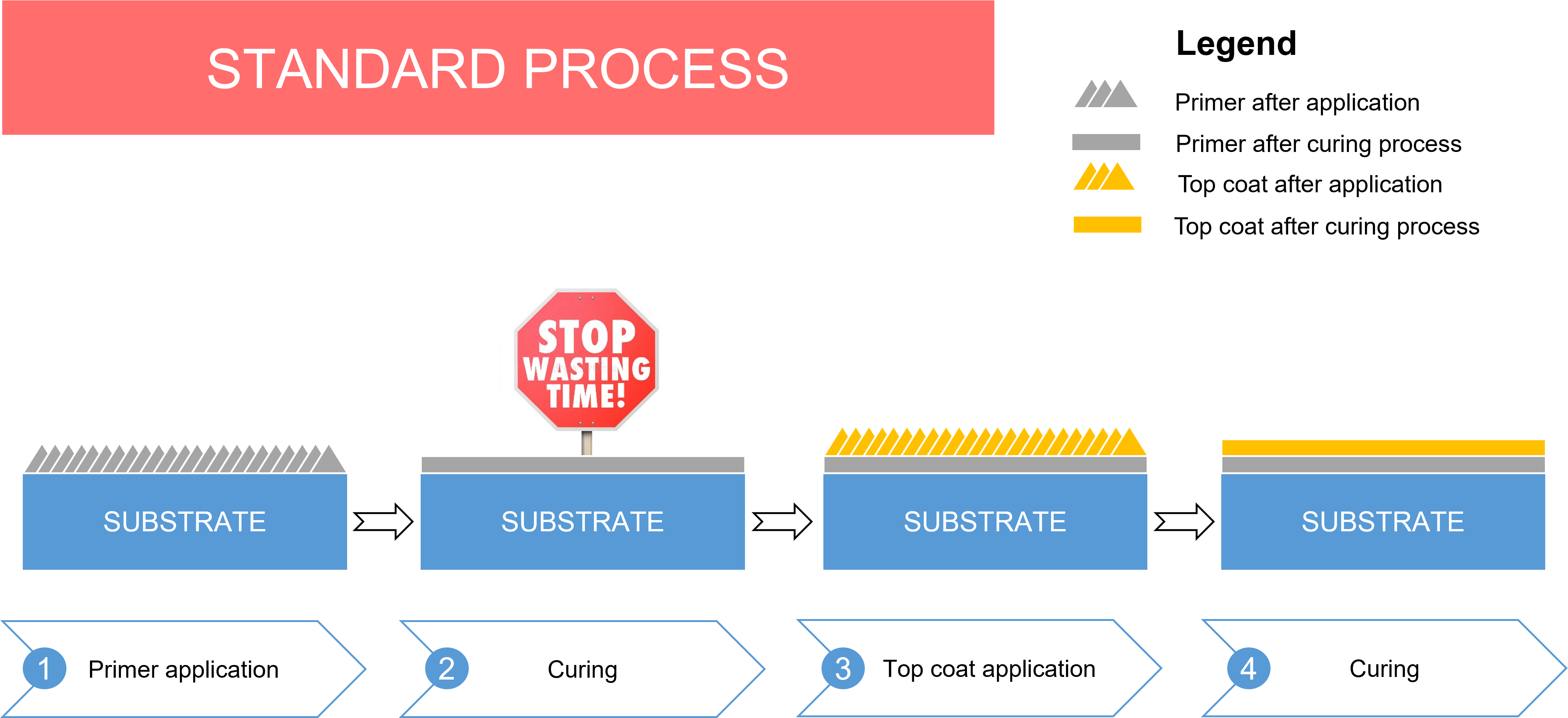

The standard industrial process is based on four phases:

In the industrial field, this work method is the most common but it involves long coating times because of the double passage in the oven of the manufactured articles.

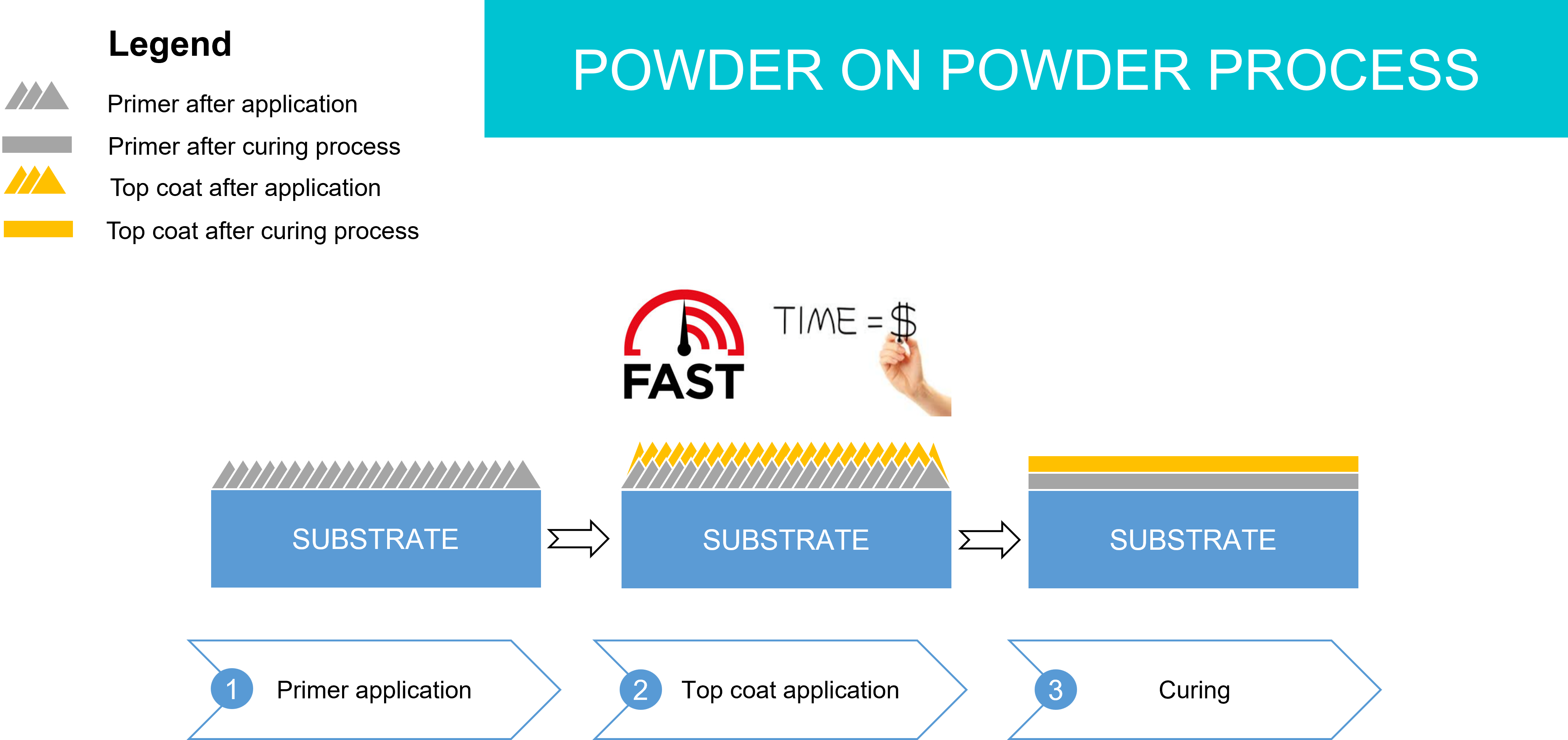

Instead, the innovative ‘Powder on Powder’ process is only based on three phases:

This new process involves the top coat directly on the primer without an intermediate step in the oven. This process is called "Powder on Powder". Generally standard powder coatings are not formulated to be suitable for the "Powder on Powder" process and they can not guarantee an optimal aesthetic effect. The inappropriate features of standard powder coatings can even lead to various problems, for example mixing phenomenon between the primer and the top coat. Another issue can be difficulties during application phase.

ST Powder Coatings S.p.A. proposes an innovative series of powder coatings called MP for the Powder on Powder process. This new series is made up of primers with high corrosion resistance performance and at the same time able to contribute significantly to cost-cut. These new primers can be utilized with several top coat provided by ST in order to satisfy all the request of the market.

The Powder on Powder process of ST Powder Coatings allows: